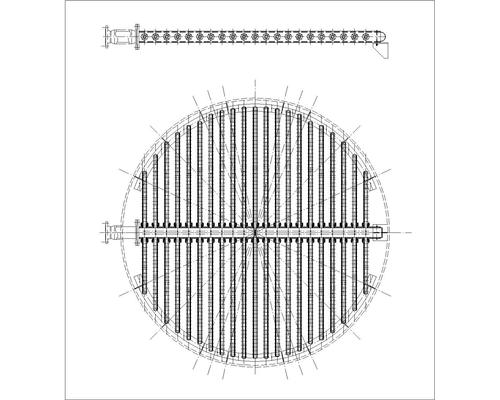

Distributor

Structure chart

Site installation diagram

Introduction

For the gas phase reaction of multi-stage feed with strong exothermic or strong endothermic reaction, the uniformity of gas flow and temperature distribution in the reactor will greatly affect the progress of the reaction. In a fixed-bed reactor with multi-stage feed, in order to ensure the uniformity of the reaction raw materials and the temperature after mixing, in addition to reasonable design to ensure the uniform distribution of the reaction raw materials at each point in the reactor, it is also necessary to ensure that the reaction raw materials are not caused by the distributor. The internal temperature changes too much, causing uneven temperature distribution in the bed.

In order to ensure uniform flow and temperature distribution, the main pipe and branch pipes of the distributor are designed with a heat preservation structure with sleeves, and the reaction gas is used as the heat preservation medium to prevent the temperature and flow caused by the excessive temperature difference between the inlet and outlet of the reaction raw materials in the distributor. Uneven distribution.

The actual operating data of the device shows that with this patented distributor, the feed temperature difference between the sections is not more than 10 ℃ in a plane.

Past performance

Xinyang Technology Group Co., Ltd. 600,000 tons/year ethylbenzene 300,000 tons/year styrene plant

200,000 tons/year styrene plant of Shandong Heze Yuhuang Chemical Co., Ltd.

100,000 tons/styrene plant of Changzhou Donghao Chemical Co., Ltd.

200,000 tons/year styrene plant of Ningbo Keyuan Plastic Co., Ltd.

60,000 tons/year styrene plant of Lijin Petrochemical Plant Co., Ltd.

POSM co-production plant of Dongming CITIC Guoan Ruihua New Materials Co., Ltd.

60,000 tons/year styrene plant of Shandong Shengyuan Petrochemical Co., Ltd.

Abel Chemical (Jiangsu) Co., Ltd. 300,000 tons/year styrene plant

Anhui Haoyuan Chemical Group Co., Ltd. 260,000 tons/year styrene plant

350,000 tons/year styrene plant of Liaoning Baolai Chemical Co., Ltd.

80,000 tons/year styrene plant of Hebei Shengteng Chemical Co., Ltd.

Anhui Jiaxi New Materials Co., Ltd. 350,000 tons/year styrene plant

Tangshan Xuyang Aromatics Products Co., Ltd. 300,000 tons/year styrene plant

400,000 tons/year styrene plant of Ningbo Huatai Shengfu Polymer Materials Co., Ltd.

120,000 tons/year styrene plant of Sinochem Hongrun Chemical Co., Ltd.

Zhejiang Petrochemical Co., Ltd. 270,000 tons/year propylene oxide co-production 600,000 tons/year styrene plant

Recommended Products

常州瑞凯化工装备有限公司

Changzhou Ruikai Chemical Equipment Co.,Ltd

Research and development, design and manufacturing of chemical core equipment

Changzhou Ruikai Chemical Equipment Co., Ltd. is located in Rulin Town, Jintan District, Changzhou. Have the third class A2 pressure vessel manufacturing qualification.

Message

Copyright © 2021 Changzhou Ruikai Chemical Equipment Co., Ltd. 苏ICP备18032196号 powered by:www.300.cn changzhou