Loop oxidation reactor

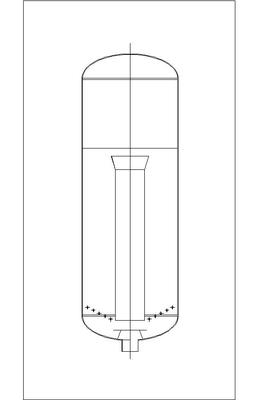

The liquid phase oxidation of cyclohexane is a free radical self-oxidation mechanism, which first generates cyclohexyl hydrogen peroxide, then partially decomposes to cyclohexanol and cyclohexanone, forming a complex mixture.

Cyclohexane reacts in the oxidation reactor R0201a~e to generate cyclohexylhydroperoxide. In the decomposers R0202a, R0202b, and R0202c, cyclohexyl hydrogen peroxide is catalyzed and decomposed to produce the expected products cyclohexanone and cyclohexanol. The acid produced during oxidation and decomposition is also neutralized in the decomposer.

The oxidation reactor and the decomposer are arranged in series. The cyclohexane from the feed heater E0202 is about 170°C, enters the oxidation reactor R0201, passes through the five series reactors in turn, and then enters the decomposer R0202a, before entering E020a, the oxidation liquid passes through the heat exchangers E0203a, b, c , Cooler E0304 is cooled to 60°C. The cyclohexane evaporated in the oxidizer is condensed by direct contact with the cold alkane liquid composed of supplementary cyclohexane and circulating cyclohexane in the condensation system.

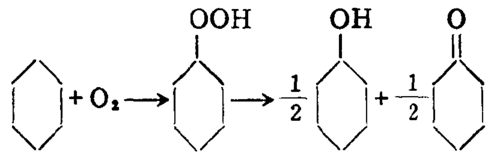

The oxidation reactor used for the oxidation of cyclohexane is a loop type. In recent years, it has been applied in the chemical industry, biochemical engineering, environmental engineering, and coal liquefaction and hydrogenation. Except for the propeller type, the loop reactor does not use mechanical stirring, but uses the jet function of the reaction fluid and the circulating flow of the fluid to agitate the reaction materials, so it has the advantages of simple structure, low cost, easy sealing and low energy consumption. . The loop reactor is very beneficial to the mixing, heat transfer and mass transfer of the reactants due to the circulating flow of the internal fluid. It is not only suitable for processing large-volume high-viscosity materials, but also beneficial to the homogeneous and heterogeneous reactions between gas-liquid, liquid-liquid, gas-liquid-solid.

Schematic diagram of loop oxidation reactor structure

The cyclohexane liquid phase oxidation reactor designed and manufactured by us is shown in the figure below. The reactor has a simple structure and reasonable design. In actual use, the reaction efficiency is high, and it is reliable and durable under long-term operation.

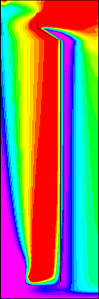

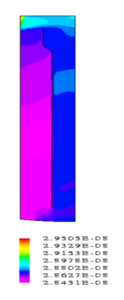

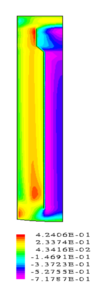

Simulation of the material flow field in the reactor

We have made scientific calculations and simulations for the actual reaction of the reactor to make the design of the reactor more in line with the requirements of the reaction process kinetics. The design of the reactor is improved step by step from the distribution of gas holdup, product and oxygen distribution, and liquid phase fraction distribution.

1. Gas holdup distribution

2. Cyclohexyl hydrogen peroxide distribution and oxygen distribution

3. Liquid phase fraction distribution

Industrial performance

Cyclohexane oxidation reactor Baling Yueyang Chemical Plant 80,000 tons/year project

Modified Trimethylbenzene Oxidation to Partial Anhydride Changzhou Boda Chemical Co., Ltd. Qian Bolin Chemical 20,000 tons/year project

Recommended Products

常州瑞凯化工装备有限公司

Changzhou Ruikai Chemical Equipment Co.,Ltd

Research and development, design and manufacturing of chemical core equipment

Changzhou Ruikai Chemical Equipment Co., Ltd. is located in Rulin Town, Jintan District, Changzhou. Have the third class A2 pressure vessel manufacturing qualification.

Message

Copyright © 2021 Changzhou Ruikai Chemical Equipment Co., Ltd. 苏ICP备18032196号 powered by:www.300.cn changzhou