Share

Maleic anhydride oxidation reactor

Regarding quality as the life of the enterprise, strictly controlling product quality, and striving to do better for customers! The various products independently produced, processed, and sold by the company meet the needs and various requirements of customers for products.

Category

Keyword: Maleic anhydride oxidation reactor

- Describe

-

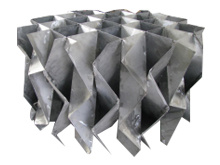

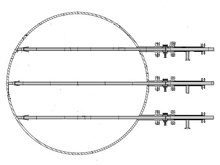

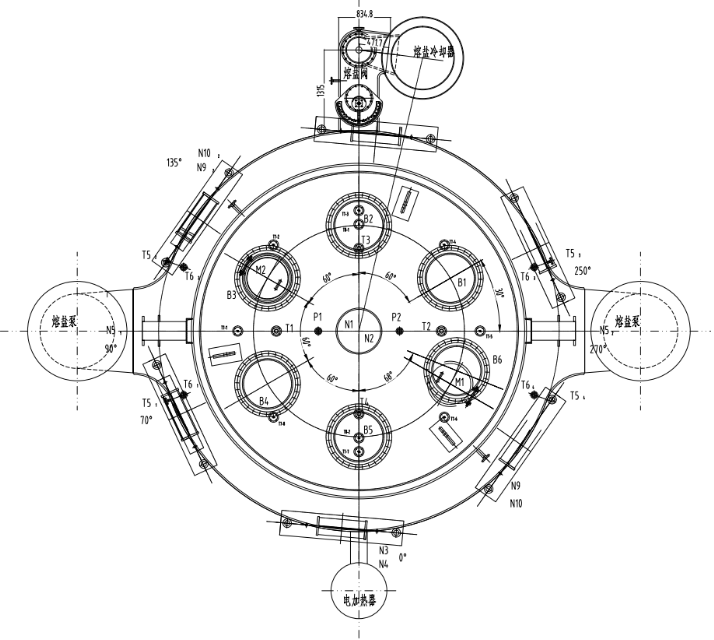

Large tubular isothermal reactors are generally used for strong exothermic oxidation reactions such as maleic anhydride, phthalic anhydride, acrylic acid, and methacrylic acid. Due to the strong exothermic characteristics of oxidation reactions, reaction tubes mostly use small tubes with a diameter of 25mm, which are operated in parallel by many tubes to achieve industrial production capacity. In industrial installations, the number of pipes often reaches 10000 to 100000. So many pipes pose significant challenges for the design of reactors, welding manufacturing, and uniformity of heat transfer media.

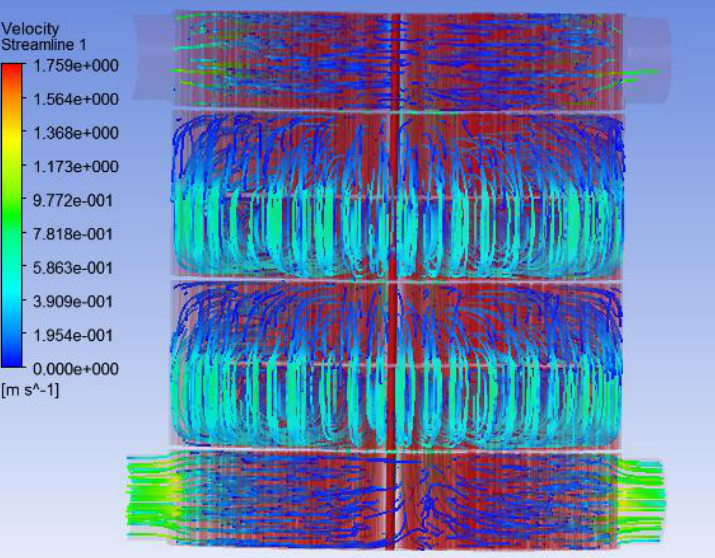

To address these issues, Ruikai conducted joint simulations on the shell side of the reactor, improving many details in the design of the reactor, including the uniform distribution of heat transfer media on the shell side, anti flash and anti tail burning treatment on the tube side, and conducting technical research and development.

At present, Ruikai has completed the on-site manufacturing of two 20000 ton/year maleic anhydride oxidation reactors. Each reactor has~18500 pipes, and each pipe needs to undergo two welding processes. A total of~74000 welding processes are required, and the one-time pass rate of on-site welding photography reaches 99%.

After the delivery of the oxidation reactor, the reaction yield of maleic anhydride will be significantly improved, and the unit consumption of raw butane will be reduced from 1.1 to 1.05t butane/t maleic anhydride. Taking the 40000 ton/year maleic anhydride plant as an example, the annual cost of raw materials alone will save~8 million yuan.

Maleic anhydride oxidation reactor

Regarding quality as the life of the enterprise, strictly controlling product quality, and striving to do better for customers! The various products independently produced, processed, and sold by the company meet the needs and various requirements of customers for products.

Category

Keyword: Maleic anhydride oxidation reactor

Related Products