Share

Dehydrogenation reactor

Regarding quality as the life of the enterprise, strictly controlling product quality, and striving to do better for customers! The various products independently produced, processed, and sold by the company meet the needs and various requirements of customers for products.

Category

Keyword: Dehydrogenation reactor

- Describe

-

This design has the following advantages:

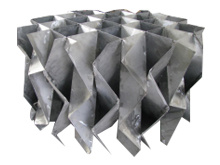

1. Minimize the catalyst bed pressure drop

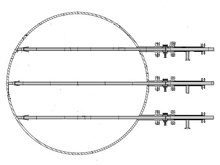

2. The reaction materials including ethylbenzene, water and air are fully mixed in the reactor, and the process meets the requirements of reaction kinetics

3. There is no coking phenomenon in the reactor to ensure the normal and stable operation of the production in a long period of time

4. The styrene yield is high, the selectivity is good, and the production index is in the forefront of the country

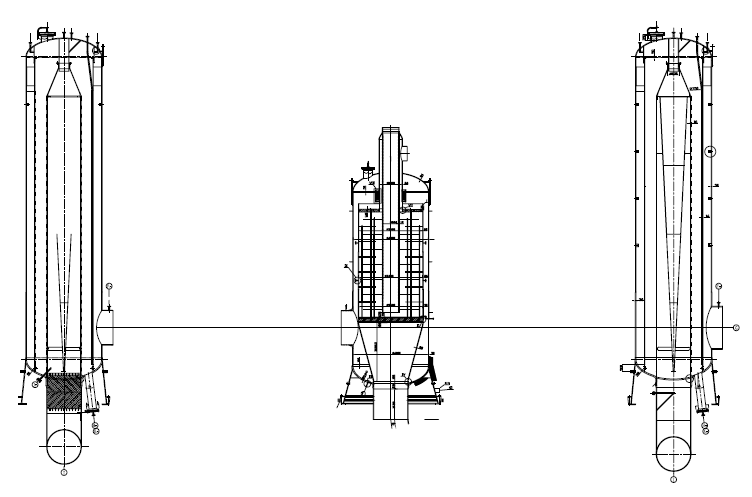

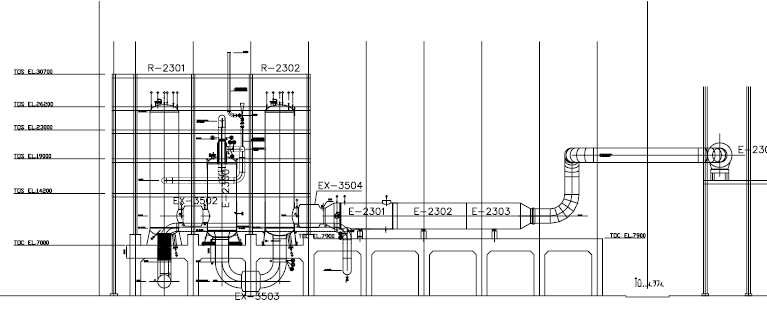

Schematic diagram of reactor system

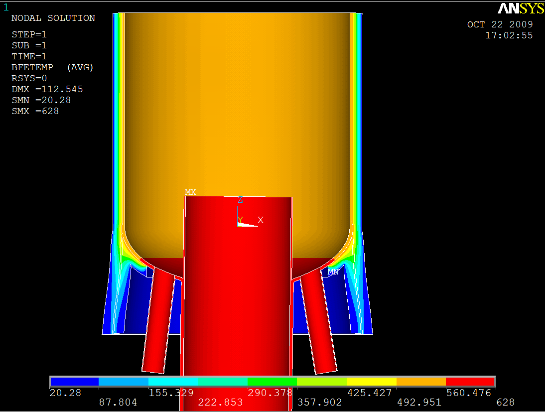

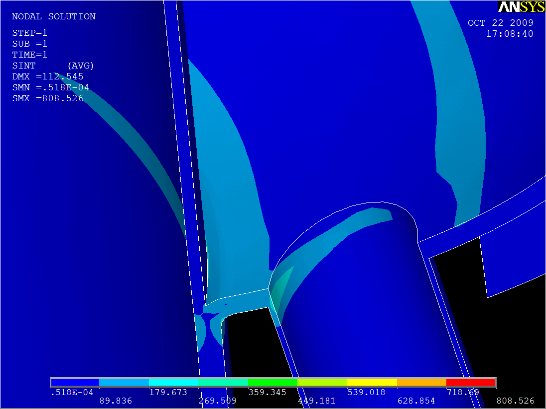

After the reactor stress analysis, to ensure the normal use of the reactor for many years at high temperature (the reaction temperature exceeds 600 degrees), to ensure safety and stable production.

Industrial performance

Xinyang Technology Group Co., Ltd. 600,000 tons/year ethylbenzene 300,000 tons/year styrene plant

200,000 tons/year styrene plant of Shandong Heze Yuhuang Chemical Co., Ltd.

100,000 tons/styrene plant of Changzhou Donghao Chemical Co., Ltd.

200,000 tons/year styrene plant of Ningbo Keyuan Plastic Co., Ltd.

60,000 tons/year styrene plant of Lijin Petrochemical Plant Co., Ltd.

POSM co-production plant of Dongming CITIC Guoan Ruihua New Materials Co., Ltd.

60,000 tons/year styrene plant of Shandong Shengyuan Petrochemical Co., Ltd.

Abel Chemical (Jiangsu) Co., Ltd. 300,000 tons/year styrene plant

Anhui Haoyuan Chemical Group Co., Ltd. 260,000 tons/year styrene plant

350,000 tons/year styrene plant of Liaoning Baolai Chemical Co., Ltd.

80,000 tons/year styrene plant of Hebei Shengteng Chemical Co., Ltd.

Anhui Jiaxi New Materials Co., Ltd. 350,000 tons/year styrene plant

Tangshan Xuyang Aromatics Products Co., Ltd. 300,000 tons/year styrene plant

400,000 tons/year styrene plant of Ningbo Huatai Shengfu Polymer Materials Co., Ltd.

120,000 tons/year styrene plant of Sinochem Hongrun Chemical Co., Ltd.

Zhejiang Petrochemical Co., Ltd. 270,000 tons/year propylene oxide co-production 600,000 tons/year styrene plant

Dehydrogenation reactor

Regarding quality as the life of the enterprise, strictly controlling product quality, and striving to do better for customers! The various products independently produced, processed, and sold by the company meet the needs and various requirements of customers for products.

Category

Keyword: Dehydrogenation reactor

Related Products