Share

VOC adsorption incineration

Regarding quality as the life of the enterprise, strictly controlling product quality, and striving to do better for customers! The various products independently produced, processed, and sold by the company meet the needs and various requirements of customers for products.

Category

Keyword: VOC adsorption incineration

- Describe

-

1.Principle

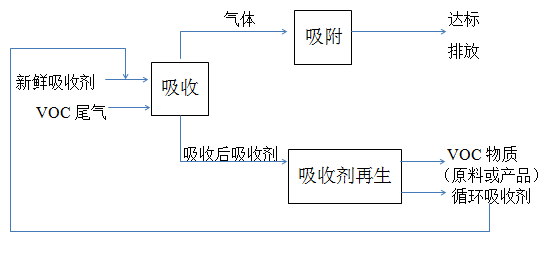

Adopt the method of combining absorption and adsorption to change the VOC tail gas with high flow rate and high concentration into low concentration VOC tail gas, and then adopt the adsorption method to remove the substances in the tail gas that cannot be absorbed by the absorption method and the small amount of absorbent entrained after absorption And the VOCs that do not meet the emission standard are removed, and the exhaust gas can be directly discharged after reaching the standard. The absorbent adopts the high-boiling liquid phase of the device and does not introduce additional impurities; the absorbent adopts a combined type, and for the types of VOCs, a multilayer adsorbent is used to ensure complete adsorption. The recovery rate of VOCs in this method is ≧99%, and the recovered volatile organic compounds can be directly returned to the production device or used as a product after simple rectification.

2. Conceptual process

3. Device features

This new process for processing VOCs tail gas has a wide range of applicability. It can treat high and low concentrations of VOCs tail gas and recover a large amount of organic matter in the tail gas. Its advantages are:

1) Device flexibility. According to the content of VOC in the exhaust gas, the scheme can be adjusted flexibly. It can not only convert VOC tail gas with high flow rate, low concentration and unstable concentration and flow rate into small flow rate, high and stable VOC tail gas for treatment, but also treat high-concentration VOC tail gas, which reduces the cost of treatment and ensures that each The stability of the device processing.

2) Reasonable adjustments can be made according to the existing equipment.

Absorbing oil can use the existing materials of the device, such as unqualified products, by-products, etc., without introducing impurities.

The adsorbent can be selected according to the material to be adsorbed and the amount of adsorption, and can be adapted to the exhaust gas treatment requirements of a variety of devices.

Fans or jet pumps can be used for exhaust gas boosting equipment.

3) High VOC recovery rate.

The substances in the VOC tail gas of enterprises are generally raw materials or products produced. Under the requirements of the emission standards, this device can recover VOC substances to the maximum extent and reduce the energy consumption of the device and the enterprise.

4) The device is small in scale, large in processing capacity, small in equipment, and small in area, which is especially suitable for the transformation of existing devices.

VOC adsorption incineration

Regarding quality as the life of the enterprise, strictly controlling product quality, and striving to do better for customers! The various products independently produced, processed, and sold by the company meet the needs and various requirements of customers for products.

Category

Keyword: VOC adsorption incineration

Related Products